Prototyping and developing wireless products can be a lengthy and challenging process, depending on whether you

start with building blocks, or work from a chip-down design, as well as the expertise you have on your team and other factors.

So — you’ve designed your wireless product, and it's time to build your prototype and get your product into production because time is of the essence, right?

Yes, but first you want to think about certification requirements. If you take a few important steps in the early stages, you can increase your chances of success in the certification process and actually improve your time-to-market.

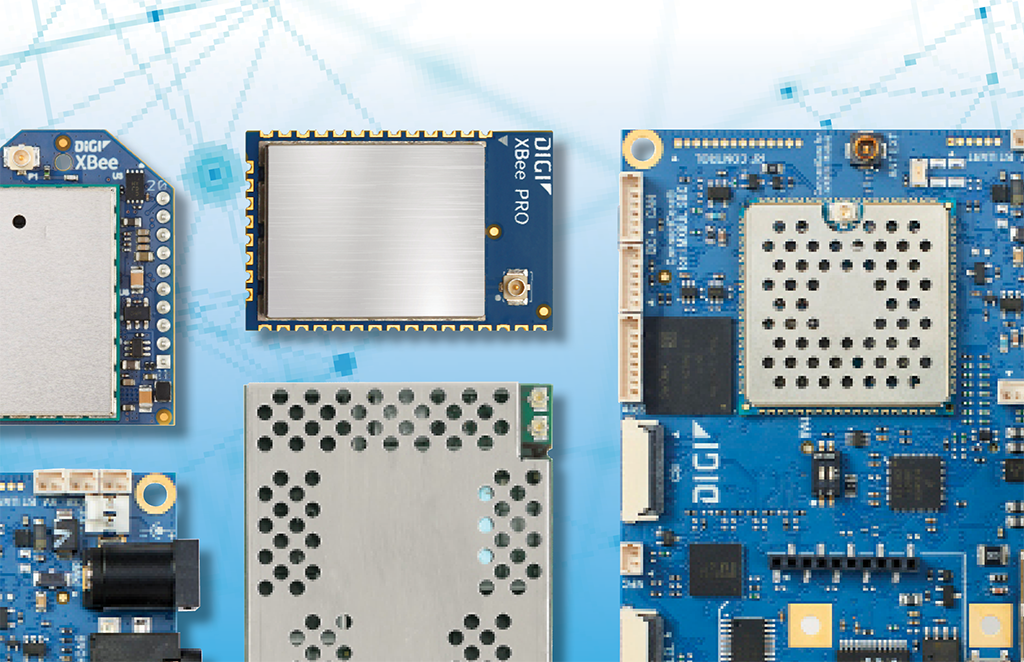

There are a few paths when designing your wireless product: use a pre-certified module, non-certified module or design your own wireless transmitter from scratch. Each path has its own complexities and design time.

Using a pre-certified module from Digi International is one of the quickest ways to market. The module is already designed and certified for some of the major countries in the world. This is usually the best path forward if you are not familiar with wireless design or the certification process.

Key Considerations for Pre-Certified Wireless Components

There are a few important things to note when development with pre-certified modules:

- One caveat to using a pre-certified module is that you need to use it in your end product as it was certified and noted in the grant. Typically this means that the end product needs to provide a separation distance from all persons and must not be co-located with another transmitter within the device. Your end product will require extra testing and certification if your end product is going to be body worn or have another transmitter build in.

- Another caveat is the countries that the module is certified for. If your end product is going to be used in a different country, then your product or module will require that new country certification.

Digi’s Wireless Design Services team can help with your end product for these caveats.

Three Key Ways to Accelerate Wireless Design Certification

Here are some important practices that can get your product to market faster, with fewer board spins and at a reduced cost:

- Build certification success into your design: It’s critical to understand the standards and tests involved in the certification process before you start to design. In Digi WDS, we often see situations where an organization launched into development without clear understanding of requirements or RF design best practices, only to have serious emissions issues with their electronics, or performance problems with their antenna, resulting in certification failures at the end of their development cycle and subsequent board spins.

The exact certification requirements vary depending upon the regions your end product will support. Certification requirements also depend on your communication method, as cellular products must pass additional certifications. See the related post, Preparing for Wireless Design Certification, to read about the most common certification requirements.

- Test at critical junctures: Testing aspects of your design along the way is a great practice. The goal is to be certification-ready and pass the first time in the actual certification process. Work with your test lab at phases throughout product development to do pre-scans and spot-check high risk areas. While this process can result in changes to your PCB layout and antenna implementation, the earlier you can identify issues, the lower your risk of failure in the formal certification process.

- When the going gets tough, outsource key aspects of your development: It is rare for engineering teams to have a full suite of experts in every aspect of design, prototyping, testing, building, and certification. Not to mention all of the critical equipment required for success at each phase along the way.

If you run into challenges or just need some assistance to put your best foot forward, a professional wireless design service like Digi’s WDS team can help. We have a full team of experts in all aspects of designing, building BSPs, testing, preparing for manufacturing and of course supporting designs that pass certification the first time.

The support you require may include anything from advising on your basic design principles to providing a complete reworking of a design that is not passing certifications. While the best possible strategy is to design for certifications to avoid failures, even failing designs can be rescued and turned into successful products that pass certifications with flying colors.

Next Steps