In the 25 years since its founding, National Control Devices has emerged as a global leader in the design, manufacture, testing, and deployment of products that make the Internet of Things (IoT) a reality. With solid accuracy, range, battery life and security features, NCD sensors, controllers, and solutions offer affordable choices for industrial and consumer applications that offer superior range, low power consumption, mesh network support, and industry certifications.

In the 25 years since its founding, National Control Devices has emerged as a global leader in the design, manufacture, testing, and deployment of products that make the Internet of Things (IoT) a reality. With solid accuracy, range, battery life and security features, NCD sensors, controllers, and solutions offer affordable choices for industrial and consumer applications that offer superior range, low power consumption, mesh network support, and industry certifications.

Moreover, NCD’s sensor solutions enable their customers across the globe to keep their fingers on the pulse of their devices, systems and remote operations. This means they can take action to reduce waste in water systems, establish energy metering systems to improve efficiency and reduce the use of natural resources, monitor and control remote agricultural operations for more precise and effective irrigation, and much more.

Keeping A Vigilant Eye on Farms, Factories, and Foods

Remote sensing and the Internet of Things continue to rapidly expand their presence across a wide range of industries, sectors, and vertical markets, thanks to the IoT’s ability to reliably and affordably monitor, report, and control far-flung operations and processes from a central location.

Consider the world of manufacturing — from pulp makers to steel foundries to car factories — where companies want to carefully track numerous metrics. Even small variances in vibration, temperature, pressure, or gases can translate into major concerns about safety, cost, product quality, and environmental impact.

In different ways, indoor agriculture requires the same level of vigilance as farmers strive to maintain narrow tolerances in temperature, humidity, soil moisture, and CO2. And in food and beverage plants, manufacturers want to keep contaminants out and also carefully track inventory levels and product quality from samples.

- From monitoring use of critical resources like water to keeping tabs on air quality and the presence of harmful toxins, to monitoring energy consumption, all of these use cases have some compelling drivers:They require sensors that can detect changes, levels or temperatures so that decision makers can gain critical insights and take action.

- Without those sensors in place, network and system managers can miss key indicators that can lead to significant financial costs, harm to the environment or create risks for health and safety.

- By gaining insights into the hourly or daily functionality of their deployed systems and infrastructure, organizations can send maintenance personnel only when needed – instead of sending fossil fuel powered trucks to remote sites just to do periodic checks.

According to Anil Bhaskar, chief executive officer of NCD, these unique IoT environments all have one common requirement: bulletproof connectivity. “When we choose our connectivity components, we need security, reliability, and strong technical support,” he said. “Reliability is even more important than price because, if the connectivity isn’t there, we’re out of business.”

Low Power, Low Cost — and High Performance

For most of its sensor deployments, NCD relies on Digi XBee® 900 HP radios for reliable and low-cost connectivity. With RF line-of-sight ranges up to 28 miles and strong interference blocking, the Digi XBee 900 HP module combines reliability and redundancy for NCD’s low-power, mission-critical wireless sensor networks.

For most of its sensor deployments, NCD relies on Digi XBee® 900 HP radios for reliable and low-cost connectivity. With RF line-of-sight ranges up to 28 miles and strong interference blocking, the Digi XBee 900 HP module combines reliability and redundancy for NCD’s low-power, mission-critical wireless sensor networks.

This module leverages unlicensed 900 MHz (or 868 MHz) spectrum and can use the DigiMesh® networking protocol, featuring redundant mesh network operation and support for low-power sleeping nodes – or operate in simple point-to-multipoint mode. These modules provide range, data redundancy, and data reliability in a small surface-mount form factor that saves valuable board space.

“Our customers like the Digi XBee 900 HP modules for a variety of reasons,” Bhaskar said. “First, the sub-gigahertz frequency makes them ideal for use in factories. They find that 2.4 GHz or Wi-Fi signals don’t have the range and bandwidth they need. What’s more, many of these locations have robots, tablets, and other devices already on 2.4 GHz, so 900 MHz is a safe choice to ensure no interference.

“Our customers like the Digi XBee 900 HP modules for a variety of reasons,” Bhaskar said. “First, the sub-gigahertz frequency makes them ideal for use in factories. They find that 2.4 GHz or Wi-Fi signals don’t have the range and bandwidth they need. What’s more, many of these locations have robots, tablets, and other devices already on 2.4 GHz, so 900 MHz is a safe choice to ensure no interference.

“In both factories and remote settings (like greenhouses or warehouses), it can be harder to provide power for sensor networks, and Digi modules are low-power, battery-operated devices, so it’s far easier to install them. And, of course, public spectrum means these solutions have no recurring costs.”

Minimizing Expensive Downtime

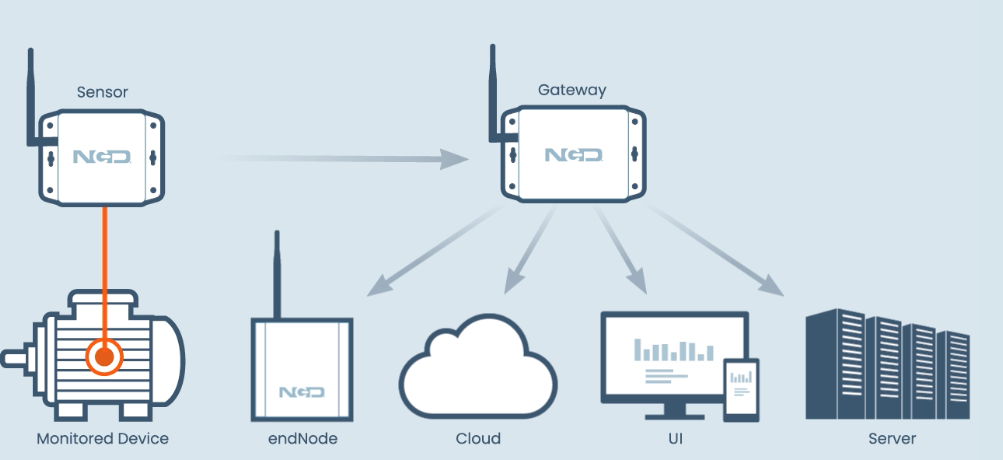

According to Bhaskar, NCD implementations use an efficient mesh network. Each Digi XBee 900 HP — encased in a molded steel or aluminum enclosure — accepts updates from as many as 48 different sensors. And with identical footprints, NCD can swap out and work with any Digi radio.

“We take full advantage of the sleep function to minimize battery usage and extend the life of the device,” he said. “It wakes up, records its samples and transmits the readings, and then goes back into sleep state. Depending on the application, this can repeat every second or every six hours. And that’s maximizing our battery life — our customers can go years without changing a battery.”

Bhaskar said that one key benefit of their solution is the ability to minimize downtime, which quickly becomes be very expensive. “One of our customers uses a massive elevator to feed raw materials to its entire plant,” he said.

“If that elevator motor stops functioning, the plant goes down. We place sensors to provide early warnings about potential failures. On one occasion, the sensor found that a bearing was about to fail. With that advance notice, they were able to pre-order the replacement and make the switch before the elevator failed. That one instance saved the customer the entire cost of our system.” Bhaskar added, “Digi has the longest range, the lowest power, mesh networking, and industry certifications that we need. It’s been an ideal choice for us and our customers.”

Next Steps