A small outfit in the U.S. Pacific Northwest designed, tested and built a sensor and automation system to help local farmers who were struggling to prevent frost damage on their crops. Frost fans are the traditional method, but they have to be started manually, at points across the farm, often at wee hours of the night. The group, G2ControlsNW, built a frost fan control system using the Digi Connect® Sensor+ and Digi Remote Manager®. Here's how the project came together.

The Challenge: Saving Crops, Orchards and Vineyards from Frost Damage

While unexpected cold temperatures are inconvenient, they can pose potential disaster for farms that raise fruits and vegetables. Even a marginal drop in temperatures during blooming periods can wreak havoc on crops, leading to spoilages, shortages, and disruptions to the food supply chain. In response, many farms use frost fans – large-bladed fans that reach as high as 30-100 feet in the air. The job of these fans is to pull warmer air down to ground level to prevent frost and preserve plant blooms.

“Even just a couple of degrees of additional warmth is enough to keep the plants from freezing,” explained Gary Gottschalk, owner of Organic Orchards, and developer of the remote monitoring solution. “By pulling the warmer air down below the inversion layer and blowing it over the plants, we can often prevent frost from forming.”

Many farms have dozens of fans dispersed across many acres or even hundreds of fans across several square miles that must be operated and managed – usually in the overnight hours when the frost risk is highest. Some of the fans have older, unreliable autostart controls. “To be honest, I got a little tired of getting up in the middle of the night and driving around for hours to service the fans,” said Chad Muenzer, owner of Muenzer Repair who installs and services the AutoStart systems in Hood River, Oregon. “I wanted an automated solution to start and stop the fans. The mechanism Gary built can automatically auto-start and stop the fan, provide smooth clutch engagement, and monitor the large V8 propane engines that drive the fans.”

The next step, however, was to build in a higher level of connectivity and intelligence to enable farmers to remotely change thermostat settings and fan directions, and monitor battery status, weather metrics and more.

The Solution: Remotely Managing and Controlling Frost Fans

.JPG?width=600&height=366)

To take fan management to the next level, Gottschalk built a complete remote-access unit for frost fans, giving farmers exceptional levels of control over their fleet of fans. The heart of that solution is the Digi Connect® Sensor+, an easy-to-deploy, battery-powered cellular gateway. Designed for rugged settings, the Digi Connect Sensor+ is the ideal way to add remote monitoring and diagnostics in places where power is not easily available. Its reliability and low data usage make remote monitoring possible in areas where it was previously cost-prohibitive.

“We looked at evaluation units from five vendors, but Digi made the choice very easy,” said Gottschalk. “Their products have a great – and well-deserved – reputation, and their support has been excellent. The Digi people are great to work with.

“We also like the fact that Digi has a complete range of solutions. For instance, in a future version, we’re considering Zigbee technologies to service areas with poor cell coverage and to reduce our power consumption. With Digi, the underlying components and designs have the same cloud services, and this kind of change would be very easy to make.”

The Results: Total Frost Fan Management and Control

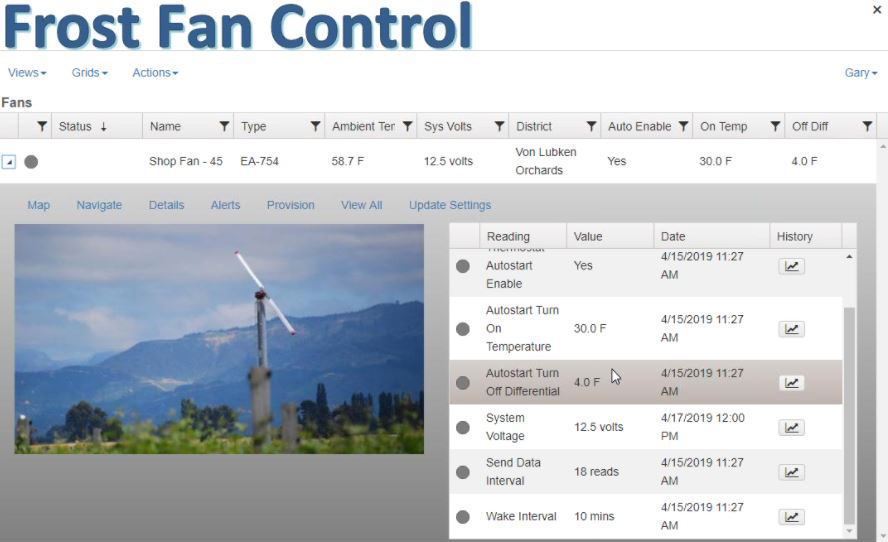

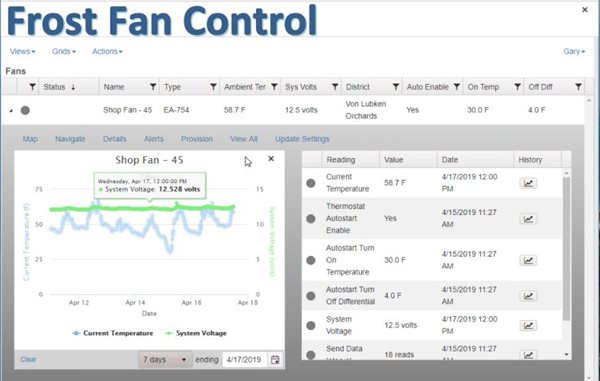

The G2controlsNW solution sends fan data through Digi Remote Manager and Digi Connect Sensor+ to a customized portal developed by New Boundary Technologies. Users can access all of that data and instrumentation from a smartphone/tablet application.

“With our solution, our users can not only manage their dozens of fans, but also remotely diagnose the health of the sensors and engines,” Gottschalk explained. “That’s particularly helpful when you have large numbers of fans to track. We can change thermostat settings, get temperature and humidity readings, redirect airflows, and monitor battery life, fuel levels and more.”

When an untimely cold snap is predicted, the farmer can set the temperature settings for the fans in the fields or vineyards. As the temperature drops below the threshold, the fan starts with an automated clutch/gear mechanism, goes through a predetermined warmup cycle, and operates until the upper end of the temperature range is reached. The system can even restart several times in one night, saving fuel if a warm front moves through temporarily.

“This gives farmers more flexibility by letting them manage their fans – and protect their crops – far more efficiently,” said Gottschalk. “There’s no need to get up on cold nights and rush from orchard to orchard in the dark to turn on fans or change settings. This means fans run more efficiently. They run fewer hours, so there’s less maintenance and lower operating costs. Good farmers are still going to monitor the fans throughout the night. We just make the whole process easier.”