As organizations generate more data from connected devices, sensors, and machines,

edge computing has become a critical strategy for saving bandwidth, time, and money. Instead of sending every data point to the cloud, edge computing processes information closer to where it is created — filtering, analyzing, and acting on data locally. This approach significantly reduces network traffic, lowers cloud and connectivity costs, and enables faster, real-time decision-making.

Edge computing (also called edge compute) is the practice of performing data processing at the edge of the network, near the physical devices, assets, or systems being monitored or controlled. By keeping latency-sensitive and high-volume data at the edge, organizations can improve operational efficiency, increase reliability, and respond instantly to critical events — without relying solely on centralized data centers or cloud infrastructure.

Jump to:

Edge computing is a powerful concept that is just now starting to hit its stride. Many organizations may not even know they need edge computing. They just want to solve challenges, and whether they are familiar with the concept or not, edge computing is the answer. Let's talk about three of the key drivers.

#1: Managing Data You Don't Need to See

The first driver is managing IoT implementations where a large volume of data is being collected at the edge. There may be limited bandwidth available to transmit all of that data, or the enterprise wants to use their bandwidth sparingly because of cost issues or usage caps on cellular data plans. And much of that data can actually be ignored.

On average, most monitoring data tends to be standard “heartbeat” data, which is information that basically says "I'm up and running." Edge devices will often send the same message each time they are programmed to wake up and report. An edge compute device can automatically distinguish between the unchanging heartbeat data and outlier data that demands attention, using a handful of checks and balances. It can thus minimize the volume of data requiring a cellular connection. If more detail is needed, you can easily request the status. Otherwise, the heartbeat data is not transmitted.

#2: Automating Processes

With an edge computing solution, a smart edge device can make a decision and take action. For example, in a deployment where an edge device is monitoring a water tank that is constantly being filled by a pump, the device can determine if the tank is full and the pump is functioning properly. When the water gets to a certain level, the edge device can turn off the pump and then report the level.

Local inputs of information, whether that's one input or 100, provide the intelligence to determine what action should be taken. Those inputs could be things like tank level, temperature, or voltage readings that indicate a battery is getting low, in which case the edge device could turn on a generator to keep the power running until the battery is replaced. Smart devices at the network edge have the ability to launch processes and turn other devices on and off. It’s worth noting here that switches, relays and actuators are different mechanisms that all serve the same basic purpose in the edge environment.

There is usually some override capability available at a remote command center. But ideally, the device will be able to take action without requiring a remote system to send a command. That's the beauty of edge computing — personnel can continue with their important tasks, and no one needs to jump into a service vehicle to drive out to a remote site. It just takes care of itself.

#3: Gaining Visibility at the Edge

The third driver is the need to gain visibility into the status of devices and processes, and important events across the network. Whether you have edge devices monitoring frost conditions, soil conditions, weather patterns or other important data, systems managers will need at-a-glance information on those conditions, and critical notifications that require intervention.

There are many examples, but one of our favorites is Wake, Inc., a company that provides sensors for concrete curing in heavy construction projects. Using Digi Connect Sensor and Digi Remote Manager®, Wake provides a complete monitoring solution that notifies project managers of any critical issues, across hundreds or thousands of concrete pours. If the concrete needs temperature remediation, teams can get notifications and quickly apply warming or cooling strategies to ensure the concrete cures properly and meets specifications.

As we've indicated, managing deployments that stretch over wide areas, such as an oil field, solar or wind farm or large construction site, requires special considerations. It would be expensive and nearly impossible to have personnel inspect every installation to make sure processes and equipment are running correctly at all times. Edge computing is a key capability in making these large IoT deployments cost-effective.

There are also some truly mission-critical use cases where machinery or equipment can potentially suffer serious damage, or lead to environmental disasters, without the immediate intervention made possible by the near-real-time responsiveness of edge computing.

For example, a moisture sensor connected to an edge device can rapidly launch a process to shut off power to protect electrical equipment in a location that is susceptible to flooding. Another example is electric utilities that operate in areas prone to wildfires. Utility companies are implementing edge computing solutions to shut down transformers in order to reduce the risk of fire. In cases like these, the relatively modest expense of deploying an edge computing solution is easily offset by the potential loss of equipment and the resulting business interruption.

Applications that Can Use Edge Computing to Save Time, Money and Bandwidth

The applications for edge compute are vast, particularly in the industrial IoT (IIoT) space, where deployments can be large, deployed over wide acreage, and exposed to varying conditions that can require action.

We've mentioned a few use use cases. Let’s take a look at some common applications for edge computing across industry sectors where time, money and bandwidth optimization are crucial.

Oil and Gas

In an oil and gas setting, a device with edge computing can monitor thresholds, inline pressure, temperature and flow rates. The goal here is to detect or hopefully prevent oil or gas leaks. Leaks are a huge problem in this industry, both for safety and environmental reasons, as well as possible fines and remediation costs. For example, if an edge computing device connected to a gas meter detects a higher-than-normal flow rate, it can automatically shut down the gas line and possibly prevent an explosion — faster than personnel could response to alerts.

Irrigation and Landscape Maintenance

In a landscape watering system, you can use edge computing intelligence to automatically check a rain gauge or soil moisture sensor before turning on the sprinklers. An edge device could even be connected to the National Weather Service so that if there’s a 70% chance of rain on a given day, or if it's too cold and there’s a danger of freezing, the edge device could turn the sprinklers off. Companies that manufacture commercial watering systems and commercial lawn management services are now adding temperature and moisture monitoring capabilities, especially in high water use applications such as golf courses and in chronic drought areas in the southwestern U.S.

Wind and Solar Farms

Today, many green technology applications such as wind, solar, hydro and even trash and recycling systems are IoT-enabled. Sensors, radios and gateways gather and transmit data about various conditions, and can then launch processes. For example, these can include adjusting the angles of solar panels, or shutting off wind turbines when they are at risk due to extreme wind conditions.

Building Automation

Edge computing is used in many smart building applications such as elevators and HVAC systems. Elevators have edge computing devices for recalibrating and adjusting for heavier loads when there are more people in a car. Edge computing also has a role in predictive maintenance, where it can generate a maintenance ticket automatically if potential problems are detected, such as a motor running at a high impedance, which could indicate that the motor is starting to wear out. Detecting and solving problems to prevent business disruption and reduce the time and expense of maintenance personnel can save businesses massive costs annually.

Many office buildings use edge computing in HVAC systems to manage heating and cooling based on whether or not people are in the building. They also have intelligent lighting controls with sensors to adjust lighting levels and even open or close window shades to take advantage of natural light or reduce thermal gain in the summer. While these systems can be managed remotely, it's more convenient and efficient and therefore cost effective if they can be managed right at the edge, without human intervention.

Edge computing systems like these can deliver substantial cost savings over time for building owners. Building automation systems with edge computing capabilities are also a great example of “green tech.” They can enable the energy-efficient best practices that help building owners earn Leadership in Energy and Environmental Design (LEED) certification for their properties. LEED certification, in turn, can be a competitive differentiator in marketing to prospective tenants who want to promote their environmental awareness.

Manufacturing Automation

Edge computing is often seen in manufacturing automation use cases such as assembly lines, where each robot or machine has its own artificial intelligence (AI) and is running itself, and then sending data to a recording server. Edge computing can detect if some condition is not up to spec, or some action needs to be taken to keep machinery functioning smoothly and safely. Machine faults, quality deviations, and safety events can be detected and addressed instantly — without the latency of cloud-based processing. This faster response time minimizes unplanned downtime, improves throughput, and helps protect both equipment and personnel.

Automated systems generate continuous streams of data from PLCs, sensors, robots, and vision systems. Edge computing processes this data locally on the factory floor, eliminating the need to transmit every data point to the cloud. By filtering and analyzing data at the edge, manufacturers dramatically reduce bandwidth usage and avoid unnecessary data transfer costs.

Today, AI, machine learning, and computer vision systems are increasingly being implemented in conjunction with edge computing. When you are using an edge computing solution to monitor a set of levels or thresholds, machine learning enables you to refine and tune them in over time. This combination of edge computing and machine learning can significantly improve quality and consistency in manufacturing.

From a cost perspective, edge computing lowers operational and infrastructure expenses by reducing cloud storage requirements, limiting network dependency, and enabling predictive maintenance that prevents costly failures. The result is a more efficient, resilient, and scalable manufacturing operation that delivers measurable savings across bandwidth, time, and total cost of ownership.

See more examples of edge computing across verticals.

Get Our eBook

Learn about Industry 4.0 technology

Download PDF

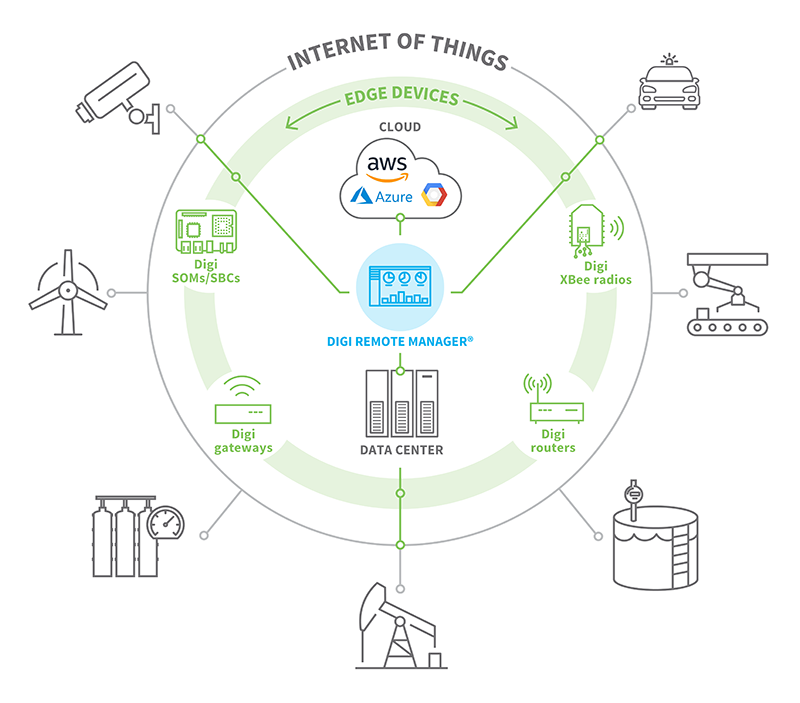

Digi supports your edge computing needs across the industrial landscape with complete cellular solutions like Digi IX20, Digi IX30, and Digi IX40 which integrate remote device monitoring and management with Digi Remote Manager® — the command center of your distributed network.

Digi supports your edge computing needs across the industrial landscape with complete cellular solutions like Digi IX20, Digi IX30, and Digi IX40 which integrate remote device monitoring and management with Digi Remote Manager® — the command center of your distributed network.

In particular, Digi IX40 is an industrial 5G edge computing industrial IoT router solution designed to support the rapid processing, analysis, and integration of industrial asset data in Industry 4.0 applications. This powerful solution supports the 5G connectivity and edge intelligence needed to enable a wide range of applications from predictive maintenance and asset monitoring to machine learning and advanced robotics.

Digi Connect® Sensor XRT-M is one of our leading solutions with edge compute capabilities. Connect Sensor+ can take regular sensor readings and it has the ability to take action, for example, by operating a switch to shut off an oil or gas line or line if a predefined threshold level is reached.

Digi Connect® Sensor XRT-M is one of our leading solutions with edge compute capabilities. Connect Sensor+ can take regular sensor readings and it has the ability to take action, for example, by operating a switch to shut off an oil or gas line or line if a predefined threshold level is reached.

Digi Connect Sensor XRT-M is often chosen for edge environments because it has alerting and trigger functionality available, as do all Digi cellular routers in the IX (industrial) series. Many customers choose IX routers specifically because they are industrial grade and able to withstand the extreme temperatures and moisture conditions found in so many outdoor industrial settings.

And if you're designing and building IoT products, Digi has you covered there as well with a full suite of embedded solutions. Digi XBee® devices, such as the Digi XBee 3 cellular modems, integrate MicroPython and can be programmed to perform various functions at the edge.

And if you're designing and building IoT products, Digi has you covered there as well with a full suite of embedded solutions. Digi XBee® devices, such as the Digi XBee 3 cellular modems, integrate MicroPython and can be programmed to perform various functions at the edge.

These devices can have the ability to wake at regular intervals and take readings, or ask the sensor to provide some specific data value, and then enter sleep mode. Digi XBee RF modules, connected to Digi's IoT gateways can also initiate a similar action.

In addition, Digi ConnectCore® system-on-modules provide a complete OEM platform for development of intelligent edge devices. This complete ecosystem includes developer kits for prototyping and testing, SOM solutions with integrated operating environments based, a suite of developer tools for rapid development and fast time-to-market, as well as value-added services for remote monitoring of end devices, and ongoing security management — Digi ConnectCore Cloud Services and Digi ConnectCore Security Services.

See our Edge Computing Technology page, and the collection of blog posts in our series on edge computing:

How does edge computing reduce bandwidth usage?

By processing data locally and only sending relevant or critical information to the cloud, edge computing dramatically reduces the volume of data transmitted over the network. This minimizes network congestion and lowers data plan costs — especially critical for large IoT deployments with limited or costly bandwidth.

In what ways does edge computing save time?

Edge computing enables real-time or near-real-time decision-making by analyzing and acting on data at the edge. This significantly reduces latency (the delay between data generation and response) compared to cloud-only processing, making operations faster and improving responsiveness.

How does edge computing save time and improve responsiveness in industrial operations?

Processing decisions locally eliminates the round-trip latency of sending data to a distant cloud and waiting for response. In applications where rapid action matters — such as shutting off a pump, detecting abnormal readings or controlling equipment — the edge approach allows near-real-time response.

How does edge computing help organizations save money?

Organizations using edge computing technology can save money by:

- Lower data-transport costs from fewer megabytes sent, fewer cellular/wan usage fees

- Fewer truck-rolls or physical site visits because local automation can act without human intervention

- Avoiding business losses from delayed responses or system failures due to slow data processing.

- Better equipment uptime and reduced downtime costs by enabling early detection and local control

What kinds of applications or use-cases benefit most from the efficiencies of edge computing?

Some strong examples of use cases that benefit from the improved efficiency of edge computing include:

- Remote installations (oil-and-gas, solar/wind farms) where connectivity is limited and latency critical

- Monitoring systems where vast streams of sensor data need reduction before forwarding

- Smart infrastructure (e.g., building automation, lighting, HVAC) where local control saves energy and cost

What should organizations think about when planning an edge-computing deployment?

Key considerations:

- Assess which data actually needs to be sent to the cloud vs what can/o should be processed locally

- Ensure the selected edge device or gateway has sufficient processing, memory and I/O to handle local analytics

- Plan connectivity and network conditions—edge helps when links are constrained, intermittent or expensive

- Ensure remote management, security (firmware updates, authentication), and lifecycle support for distributed devices

- Define clear metrics for your deployment: bandwidth cost savings, response time improvements, site visit reductions

How does edge computing improve reliability?

Since edge systems process data locally, they can continue operating even when cloud connectivity is limited or interrupted. This increases reliability and reduces downtime — especially in remote or distributed environments.

Does edge computing only benefit IoT applications?

While IoT use cases (like sensor monitoring and automated control) are major beneficiaries of edge computing, any application that needs fast processing, reduced data transfer, and efficient network usage — such as smart buildings, industrial automation, and video analytics — can benefit.

Next Steps

Note: This blog post was originally published in May of 2021, and was revised in May of 2024 and again in November 2025.