The world of IoT is one where complementary technologies are constantly producing new and innovative capabilities. Among the most promising of these match-made-in-heaven technologies are machine learning (ML) and machine vision (MV). Let's explore how medical and industrial IoT (IIoT) applications are advancing with the capabilities of these technologies.

This article is based on a paper co-written with Brad Scott, CEO of AuZone Technologies, Inc. leading up to a presentation on machine learning technology for Embedded World 2020. At the same time, Digi launched the Digi ConnectCore® 8M Nano Development Kit.

The Digi ConnectCore 8M is a member of the ConnectCore family of powerful, scalable SOMs (system on modules), tools and services, designed for rapid development and fast time-to-market. Join our mailing list to receive announcements about new products and upcoming events from Digi!

How Machine Learning (ML) and Machine Vision (MV) Are Changing Our World

Machine learning techniques can be applied to a wide range of machine vision image processing or classification tasks. And, thanks to the scale at which these applications are being adopted, it is rapidly becoming cost-effective to add machine learning and machine vision capabilities to an increasing variety of IoT products.

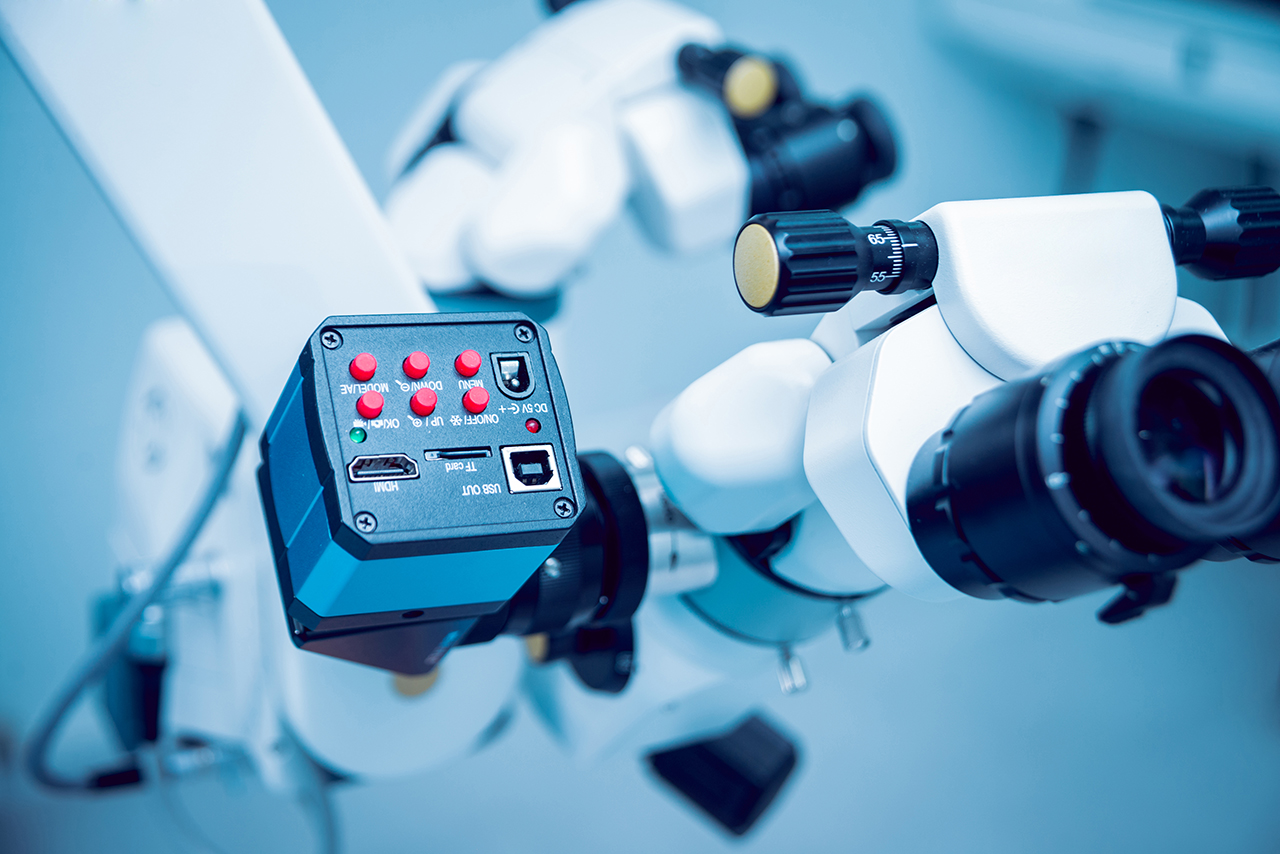

Machine vision systems typically use digital sensors inside of industrial camera modules where images are processed and analyzed. When used in conjunction with machine learning, machine vision applications can perform complex tasks reliably and consistently.

In healthcare applications, for example, they can monitor patients or detect anomalies in radiological images, improving patient care or even saving lives.

In an industrial environment, they can provide quality control inspections of many identical items on a conveyor belt without error or fatigue. In fact, machine vision can deliver cost savings and quality control benefits in almost any mass production process that requires visual monitoring. Machine vision has the potential to reduce human error and provide better quality control at lower cost.

Business Benefits of Machine Learning Combined with Machine Vision

While there are many benefits of the combined power of machine learning and machine vision, some of the most important are those that drive real-world operational improvements and impact the bottom line.

- Higher product quality: Inspection, measurement, gauging and assembly verification.

- Increased productivity: Routine, repetitive tasks can be performed quickly and automatically, freeing staff for higher value activities.

- Lower costs: Adding machine vision capabilities to equipment can improve performance and extend service life. Machine vision systems in a factory setting also take up less room than human operators and don’t require the same level of safety infrastructure.

Why Compute at the Edge?

ML/MV applications necessarily function in real time. So, while many systems rely on cloud-based computing for machine learning, there is a growing trend toward implementing this processing at the application edge — that is, in close proximity to where the business process or function is actually taking place. Edge computing is especially advantageous in situations where bandwidth or latency are a constraint, such as in a manufacturing facility where dozens of items per minute may be rolling by on a conveyor belt, being inspected by an ML/MV system.

Performance Benefits of Edge Computing

Today, more of the compute effort is moving to the edge for massive improvements in efficiency and performance, including the following:

- Reduced latency: Edge computing allows a quicker response to local events. The system can respond faster because no round-trip of data to the server is needed.

- Ability to operate offline: In case of a communications disruption, the system can collect, store and process data on its own.

- Reduced cost: Reduced flow of data over the network results in lower networking costs — for example, with cellular connections which require data usage.

- Reduced power consumption: Network connections are power hungry. Sending less data can help save power which can be advantagous in battery-powered IoT devices.

Tools and Software Support Successful Implementations

Creating a machine learning solution is no small feat, and choosing the right hardware, development tools, and software components for machine learning-based image processing at the edge can go a long way toward assuring a successful implementation.

Au-Zone Technologies, for example, offers a toolkit specifically designed for the development of machine learning-based imaging systems on performance constraint embedded devices. The company’s inference engine supports MCU, CPU and GPU cores with one standard workflow and model format, providing flexibility and portability across platforms. The Digi ConnectCore® 8X system on module (SOM), in turn, contains MCU, CPU and GPU processing cores, allowing the inference engine to efficiently run on any of these compute resources. These two solutions are therefore also complementary technologies.

Discover, Scale, Innovate

We are still in the early days of what is sure to be an extensive process of development and implementation of machine learning and machine vision capabilities, with highly anticipated results. The innovative organizations that deploy these systems first stand to gain a competitive advantage as new business benefits are realized, and new use cases present themselves. These organizations will also gain the experience and expertise needed to scale their implementations into additional use cases and take full advantage of the technology as it is expanded and refined.

Reach out to Digi for guidance on the right technology for your product development, or for support with any aspect of your design and build process.